Solutions 360o

Delighting customers with our range of products and services.

Our business verticals

The Kala Jyothi advantage is expertise developed through decades of experience, technological enhancements and strategic infrastructure investments. Kala Jyothi today provides a gamut of print solutions to its customer. Kala Jyothi’s specialised business verticals help to focus better on a continuously increasing customer base with diverse range of printing needs.

Quality meets Capacity

In the everchanging publishing landscape, one thing that customers stand by is a great quality and feel of physical print!

Ranging from high quality, premium glossy magazines for international brands printed on heat-set web offset machines, to high-volume orders of export and domestic textbooks printed on quality cold-set machines with section sewn, perfect bound or saddle stitched binding, Kala Jyothi boasts a high-volume and high-quality production capacity.

Education school books

- 4,00,000 Perfect bound books per day

- 5,00,000 Saddle stitched books per day

- 2,00,000 Section sewn + Cover-drawn-over books per day

Novels & religious books – Section sewn hard & soft bound books

Newspapers

Capacity: 2,00,000 multicolour newspapers per day.

On the shop-floor

578mm cut-off heat-set web offset machine for multicolour printing with high precision colour management producing 6,00,000 impressions of 16 pages per day.

Closed loop inking system is installed on Komori 38S and GOSS machine for automatic inking corrections to ensure colour consistency at high speeds

578mm cut-off heat-set web offset machine with high precision colour management and closed loop colour inking system from QI provides for 100% backup for heat-set printing producing 5,00,000 impressions of 16 pages form per day.

Cityline cold-set web offset – 4 colour X 4 tower machine with 546mm cut-off producing 12 lakh x 16 page sections per day.

Hiline cold-set web offset – 2 machines of 4 colour X 5 towers each with 546mm cut-off, producing 24 lakh x 16 page sections per day

Sheet fed offset printing machines – A fleet of multicolour conventional and UV printing presses with online aqueous coating and UV coating options.

Perfect binding lines from TSK, Wohlenberg, Kolbus and Muller Martini with a combined capacity of 4,00,000 perfect bound copies per day.

Multiple lines of Muller Martini saddle stitching machines with combined capacity to bind 5,00,000 books per day

A fleet of Aster section sewing machines with combined capacity to sew 8,00,000 sections per day.

Variety of aqueous and UV coatings and a range of finishing operations such as Foiling, Embossing, Die-cutting, Lamination and Spot UV are available for publication’s covers and advertising innovations.

578mm cut-off heat-set web offset machine for multicolour printing with high precision colour management producing 6,00,000 impressions of 16 pages per day.

Closed loop inking system is installed on Komori 38S and GOSS machine for automatic inking corrections to ensure colour consistency at high speeds

578mm cut-off heat-set web offset machine with high precision colour management and closed loop colour inking system from QI provides for 100% backup for heat-set printing producing 5,00,000 impressions of 16 pages form per day.

Cityline cold-set web offset – 4 colour X 4 tower machine with 546mm cut-off producing 12 lakh x 16 page sections per day.

Hiline cold-set web offset – 2 machines of 4 colour X 5 towers each with 546mm cut-off, producing 24 lakh x 16 page sections per day

Sheet fed offset printing machines – A fleet of multicolour conventional and UV printing presses with online aqueous coating and UV coating options.

Perfect binding lines from TSK, Wohlenberg, Kolbus and Muller Martini with a combined capacity of 4,00,000 perfect bound copies per day.

Multiple lines of Muller Martini saddle stitching machines with combined capacity to bind 5,00,000 books per day

A fleet of Aster section sewing machines with combined capacity to sew 8,00,000 sections per day.

Variety of aqueous and UV coatings and a range of finishing operations such as Foiling, Embossing, Die-cutting, Lamination and Spot UV are available for publication’s covers and advertising innovations.

Komori System 38S - 578mm Cut-off Heat Set Web offset machine for multicolour printing with high precision colour management producing 6,00,000 impressions of 16 pages per day.

Closed loop Inking System is installed on Komori 38S and GOSS machine for automatic inking corrections to ensure colour consistency at high speeds

GOSS M150 - 578mm Cut-off Heat Set Web offset machine with high precision colour management and Closed loop colour inking system from QI provides for 100% backup for Heat set printing producing 5,00,000 impressions of 16 pages form per day.

Cityline Cold set web offset – 4 colour X 4 Tower machine with 546mm cut-off producing 12 lakh x 16 page sections per day.

Newsline Cold set Web offset – 2 machines of 4 Colour X 5 Towers each with 546mm cut-off, producing 24 lakh x 16 page sections per day

Sheet Fed Offset Printing machines - A fleet of Multicolour conventional and UV printing presses with online Aqueous coating and UV coating options.

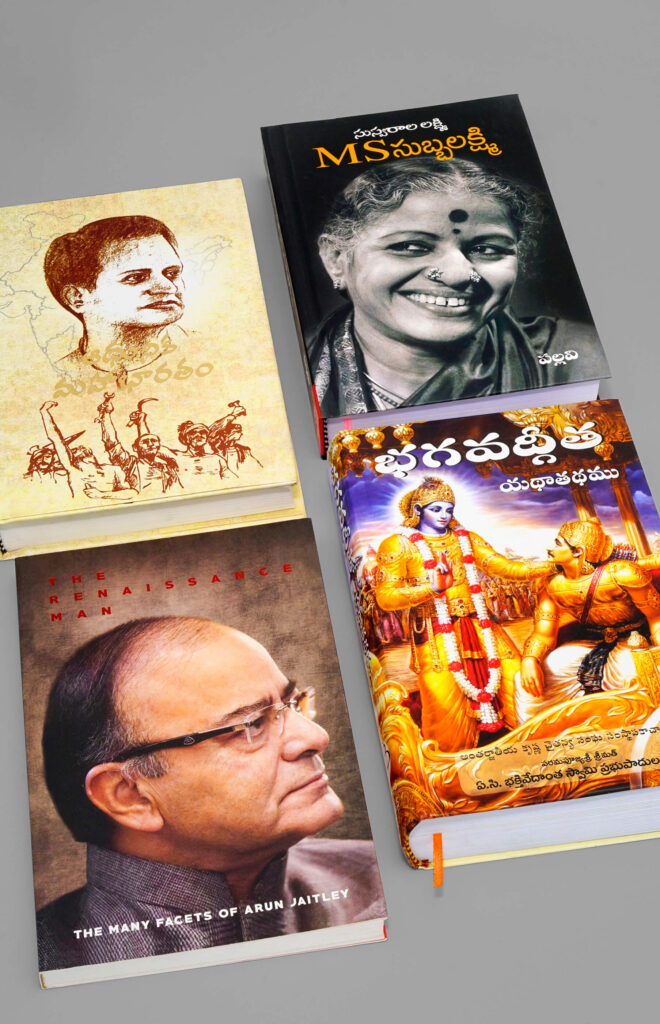

Our publishing client partners